Electrical heat tracing (EHT) can overcome these challenges by keeping products at an optimal temperature, lowering viscosity and ensuring that they are easier to transport around the plant during the colder months.

Explains Giles Maynard, general manager of eltherm South Africa, a global EHT supplier: “Electrical heat tracing can assist plant and process managers alleviate stubborn viscosity sensitive products and processes. This has the benefit of ensuring that pumps don’t malfunction due to cavitation and pipes don’t get blocked, mitigating costly repairs and maintenance.”

The term viscosity refers to the time it takes for an amount of product to run through a pipe. For example, water has a low viscosity as it flows more freely than honey. Liquids like honey and oil have a higher viscosity because they contain more complex molecular structures.

Temperature can manipulate the viscosity of liquid. When the temperature drops, liquids like syrup develop a higher viscosity and become more difficult to pour. However, when it is heated, the molecules become more excited and begin to move which lead to lower viscosity.

EHT lowers the viscosity of many processes as it acts as a compensating heat source to maintain or raise the heat in pipes, tanks, surfaces and other vessels. It effectively replaces the heat loss in the process and can therefore be used to prevent pipes from gelling or freezing, whilst maintaining the low viscosity of the process on plant equipment.

Colder days and the resultant higher viscosity can also impact domestic water supply as well as the reliable drainage of rain and waste water leading to freeze damage and ultimately frozen and burst pipes.

“To prevent freeze damage, electrical heat tracing can be installed on these pipes, preventing them from freezing without any additional insulation. A customised, self-regulating heat tracing solution is developed, installed and monitored to ensure pipes are warm enough throughout the winter months,” says Maynard.

Electrical heat tracing can maintain and lower the viscosity of liquids in many industries and applications such as:

- Resins, epoxies and adhesives;

- Petrochemical industry;

- Bitumen;

- Food & Bev such as glucose, chocolates, fats, vegetable and palm oils and other syrups;

- Automotive manufacturing processes such as glues and oils;

- Brewing – maltose and dextrose.

Heat tracing - Choosing the right system

It is highly customisable and available in both electrical and steam options. However, to understand the fundamentals of heat tracing, it’s important to know the differences between electrical heat tracing (EHT) and steam heat tracing which both offer energy and cost savings in its respective applications.

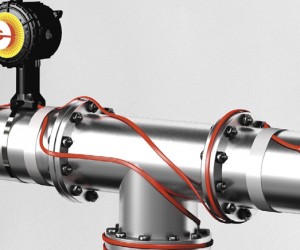

Throughout its history, EHT has been the safe choice for pipe and equipment heating as it can be regulated to deliver precise outputs. EHT essentially uses an electrical heating element that runs the length of a pipe; this heating element is then used to regulate temperature.

EHT is recommended for use on both metallic and non-metallic, as well as lined piping and process equipment as it is equipped with controls to keep process temperatures within specific limits and conserve energy.

“EHT systems offer a broad range of temperature options; it can be designed for applications with low freeze points right up to very high (800 -1000 degrees Celsius) process maintenance temperatures. It can also be installed on short or long pipelines which makes it ideal for large concentrated solar power (CSP) farms and petrochemical plants among many other applications,” explains Giles Maynard, General Manager at eltherm South Africa.

Lastly, the common misconceptions that EHT can’t be installed in Ex areas is false. Just like steam tracing, EHT has seen major technological advancements allowing them to be installed anywhere.

Steam Heat Tracing – quick heat up

Steam heat tracing is a great solution in plants where steam is a by-product of various manufacturing techniques.

Simply put, steam heat tracing systems circulate steam around process pipes to heat them. The steam tracing is usually installed by running the steam lines in direct contact with the piping or vessels to be heated. The entire assembly is then insulated to direct the heat into the process fluid.

Says Maynard: “One of the main benefits of steam is that it heats up quickly as the highest rate of heat transfer occurs when the difference between the steam tracing and the piping is the highest. This is particularly beneficial during a plant shutdown.

What to consider

From the above it’s very clear that both EHT and steam heat tracing play an important role in maintaining temperatures. However, EHT does offer less drawbacks and drives down operational expenditure (OPEX).

Explains Maynard: “EHT systems are generally easy and quick to install, use energy efficiently and offer low maintenance costs and can be monitored remotely. Also, many systems today make use of self-regulating cables which optimise the temperature control process.”

“Steam heat tracing is quite cumbersome and time consuming to install and can’t be used on non-metallic pipes. Furthermore, it’s far more expensive to maintain as it make use of fittings which have a propensity to leak. Overall, steam heat tracing has a much higher OPEX.

“Ultimately there is no cookie cutter solution, each system requiring heat tracing should be evaluated individually. There is no doubt that both EHT and steam heat tracing have an important role to play in the different environments and industries they are developed and designed for. The key is to do proper homework, consult with the experts and install a system that will future proof your investment,” he concludes.