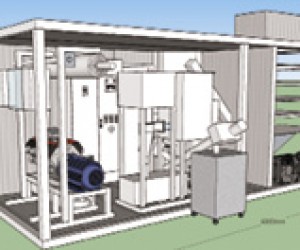

With its containerized or skid mounted and framed structure the GasiFlex™ 50 is a flexible, easy to operate and easy to relocate unit that can be erected nearly anywhere if the proper woodchip raw material is available.

The technology comes from Austria where wood production, wood industry and the energy-oriented use of biomass (e.g. woodchips) has a great tradition for centuries. Nowadays the most popular size of biomass-based power plants is smaller, while below 500 kWe/h output higher feed-in tariff is defined.

The GasiFlex™ 50 was designed and engineered in the days when the "small is beautiful" slogan became reality again and the novel machinery and control system has enjoyed prompt attention on the markets first in Europe and then afterward in overseas territories. The international designing team of Technopa upgraded and optimized their already existing and properly functioning 20 kWe/h wood gasification unit and their work resulted from the sophisticated CHP equipment with 50 kWe/h and 85 kWt/h output capacity, with minimal maintenance requirements.

Besides being a masterpiece of craftsmanship in all details, the GasiFlex™ 50 has two main extraordinary features that sharply differentiate them from other vendors' plants: the GasiFlex™ 50 eliminates tar deposits with a sophisticated gasification chamber and with well-adjusted conditions in the chamber, the other specialty of the gasifier the tolerance to humid feedstock.

The operators can easily load into the hopper wood chips with even 20% humidity—this high humidity level is normally not acceptable in other technologies.

Moreover, an optionally available built-in dryer enables the operator to use wood chips up to 30% humidity as well. The special feature also the unmanned operation and remote monitoring via the Internet.

As per Mr. Peter Pokorny, the dynamic Managing Director of Technopa GmbH told the Austrian company has a large, well-equipped factory that has already started the serial production of the gasifier.

He hopes that the decentralized small power plant system will assist also the electrification program in South Africa, especially in remote areas.

Though the GasiFlex 50 has nearly no maintenance demand, a local team of South African technicians will take care of warranty servicing in the country. The small footprint is also a benefit.

As the Managing Director says: “We establish small power plants even in the backyards if needed”.